Is Perfection A Bad Thing?

5 Steps to Make Progress Over Perfection and Achieve High Quality Results

And spent most of that time wondering whether you should keep going or if it’s good enough as it is? Wondering how you’ll know when it’s actually the right time to stop and step way?

If so, you’ll probably sympathise with the question posed recently, by a member of The Product Academy Facebook group (which you can join here!). One member wanted to know how she could better manage actually making progress, over constantly striving for perfection, when making the products she sells?

Lean Six Sigma

I trained in Lean Six Sigma* a few years ago and also once managed a quality assurance team. So it’s not so surprising that this question brought out my inner quality geek straight away! (*Lean Six Sigma is a method for improving business efficiency and quality)

So, this week I decided to share 5 steps to make progress over perfection and achieve high quality results.

The same principles apply to the production of anything – a product, an offer, a webpage, even this blog!! (Which definitely didn’t get published in its first draft and certainly still isn’t perfect… )

So, is perfection a bad thing?

We definitely want what we’re working on to be good for our customers – or what’s the point? Spending any time at all on something if it’s not going to sell or, even worse, be returned by a customer as faulty, is a complete waste of time, money and resources like parts and materials. If you want your products to be seen as a premium range, that goes hand in hand with high quality.

Aiming for perfection isn’t a bad thing in itself. Nature is pretty good at it and if you’ve ever searched for just the perfect “thing” for ages (shoes, bag, house??) you’ll know yourself just how exciting it is when you finally find it! However, the strive for perfection also comes at a cost.

As a business owner, I’m sure you are constantly juggling different demands on your time – and I’m yet to encounter a business that has spare money to throw away.

Spending longer on something than is truly necessary is a waste of your precious time. And making, scrapping, re-doing a product or even part of a product ultimately means we are wasting money. And, if you are remotely concerned with sustainability, wasting resources is as unsustainable as it gets.

So, our Step 1 is to realise we need to:

- Strive towards perfection rather than for perfection. Instead keep it in your sights as something you are always aiming towards. Continue to review and improve how you work so that you are always moving a little closer to it, without the overwhelming pressure of trying to actually get there.

Perfection doesn’t exist as a universal truth. There is always a context to what is desirable and a limit to what is achievable. Nature is pretty good at it sometimes but us mere mortals haven’t mastered it yet 🙂 Accepting that perfection is impossible makes it far easier to let go of the idea that you can achieve it.

What is perfection to me, may not be perfection to you. What is perfection to one of your customers, may not be perfection to another. If you think about the things you have searched high and low for – if they were perfect for everyone, every time, there would simply be no other products on the market.

When you’re making your products, how exacting do you need to be? It’s entirely dependent on what you’re making and what your customer wants. If you’re precision engineering parts for a premium car brand, you’ll be using lasers to measure and shape. If you’re handmaking cards, then a ruler is probably going to be fine for any straight lines or edges. If you’re an illustrator, hand drawn might just be “perfect” for your customers, who want that look and feel. A too “perfect” line might spoil your product completely.

Which brings us to Step 2 – to know what’s right for your business, you need to:

- Find out what your customers want and expect. After all, it’s what they think of your quality that really counts.

The most direct way is to simply ask them via surveys or feedback forms. The information you get back may be immediately useful. If they tell you they are or aren’t happy with the quality levels, then you know!

If their answers are a bit ambiguous, you might need to get a bit more analytical with the information you have available.

-Have your customers got requests or suggestions for improvements? If these are consistent across multiple customers it can be a fairly clear indication of a need.

-If you have product returns, what are the reasons they are being sent back? Again, if these are consistent a fix may be needed.

-If you aren’t getting returns, how many of your customers are buying second purchases from you or actively recommending you? This is an important measure for almost any company because it’s easier to sell to someone who has already bought from you. If those people aren’t happy, you are going to have to continually chase new customers.

Once we have this information, we need to do something with it!

We can use the information we’ve gathered so far for Step 3: (This is the one that will save your sanity as well as your money!)

- Establish your quality standards upfront – not product by product.

Find out what is not acceptable to your customers (Step 2) and use these to work out what types of problems you will not allow in your finished product. This will stop you from debating with yourself over and over, each time you make something. Instead, you can refer to your standards and make a conscious decision whether it’s good enough or not based on actual information.

Look at your product and what customers are telling you about it. What are they using it for, how are they using it, what do they like about it? What could go wrong with any of those aspects? What will affect their use or their enjoyment of it? These are areas you need to have standards for.

The standards can be refined over time (aka Step 1) but if you’re changing them every time you use them, that defeats the purpose. Set yourself a duration for how often you are going to review and update them. Initially, this may be quite frequently, maybe 3-6 months but eventually, 12 months may be enough.

Once you’ve got your standards in place, you can use these in Step 4:

- Get it right the first time. Design a production process that is accurate and easy to repeat and prevents mistakes happening in the first place. This minimises the chances of finding something you don’t like and getting stuck in the spiral.

When designing your process you should know the window of time you can allocate, what you can afford it to cost, as well as how you are meeting your quality standards at each step of the way. You’ll quite often hear quality professionals say ” you can have it fast and cheap, but it won’t be very good or you can have it fast and good but it won’t be cheap”!

Even big industries with the big budgets don’t have perfection: Cars develop faults, PCs freeze, bestsellers have typos. This is because there comes a point where the cost of improving quality further outweighs the benefits of having that extra quality.

The consequences determine the right spend and effort. No one is going to die if the printing on a chocolate bar is wrong. They might die if the wrong ingredients were used. What if the printing didn’t indicate the right ingredients? When I managed quality for mobile phones, our highest standard was reserved for emergency calling capability (999). No chances were taken on someone being able to call for help when they needed it.

Look at each standard you have set and design a process that pays more attention to the quality of areas critical to your customers.

If you follow all of these steps then you’ll be striving towards the right quality standards for your customers, in the right way, and the right time and the right cost. Sounds easy? Well, there is one last block in your path I’m afraid…

So far, I’ve talked about the business aspect of quality. But in a small business where we are making all the decisions ourselves – and often even actually making the products – we all know our minds have a pesky habit of interfering in even the best-laid plans.

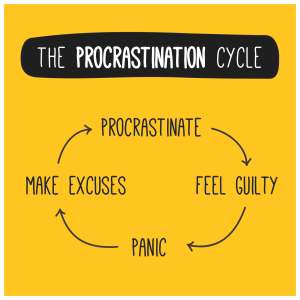

Procrastination anyone?

I think overcoming procrastination has to be the most searched for phrase for small business owners! When you think of procrastination you might think about doing anything that means you can avoid work. But procrastination comes in many forms 🙂

The next time you feel the need to keep making improvements, remember to check in with Step 5 and

The next time you feel the need to keep making improvements, remember to check in with Step 5 and

- Be honest with yourself about what your motivation is for continuing to work on it.

Are you doing it because you really believe there is a fault your customer will identify and have an issue with? Or could it be

because the product is like your baby and it’s unbearable to think of anyone finding something wrong with it?

because once it’s out there in the world it can be seen and judged by others and you aren’t ready for criticism?

because once it’s finished you actually have to do the next thing in the process? And maybe that bit is hard, boring or you’ve just never done it before? (This one is often my own nemesis!)

or any other of countless reasons that are more about you than your customers?

All of these fall into the “make excuses” part of procrastinating. And we can fool ourselves for a while that we’re working really, really hard on our product (or blog, or website…) but really, we’re just avoiding something else – which is most definitely procrastinating!

If you think your mind might be playing games with you, it’s time to take a deep breath and trust in the previous steps to deliver the quality you need.

If the fear or worry is too strong, then delving more deeply into what you’re worrying about can help. This isn’t a blog about mindset specifically (there may well be one in the future) but reading positive feedback from customers can remind you that you have put good stuff out there already. Or perhaps play out “what’s the worst that could happen?” and see if it’s really that bad. It’s usually not.

And if all of that fails, ask yourself is what your scared of really big enough that you are going to let it stand in the way of your business dreams?

So that’s it. That’s the 5 steps.

- Strive towards perfection rather than for perfection.

- Find out what your customers want and expect.

- Establish your quality standards upfront – not product by product as you go.

- Get it right the first time.

- Be honest with yourself about what your motivation is for continuing to work on it.

Implement each of those and you should feel more confident that you are using your time productively AND delivering products that meet your customers’ expectations. Two of the most important foundations for a successful business.

I would love to hear your thoughts in the comments. Was this helpful, do you have any questions? If you’ve already put quality steps in place in your business already, what’s worked well for you?

You can implement all of these steps yourself but if you would find it quicker and easier with some expert help, get in touch and let’s talk about how I can support you.

About the Author

After two decades working in mobile telecoms, with some of the most popular brands in the world, I am excited to be able to share what I learned with businesses ready to grow to their next level. You can read all about my start in the world of products here – and you’ll see why I believe we can all learn what we need to know, when we need to know it! Prior to starting The Product Academy, I worked in Mobile Telecoms for 2 decades, working with some of the most popular brands in the world. I have always been passionate about customer focus and my professional background includes strategic development, operational excellence, product management and quality assurance, marketing programme management and people development. (whew, you can do a lot in 20 years!!) Along the way, I’ve been mentored, taught and coached by some brilliant people and I’ve also learned my own lessons about what works, what doesn’t work and how to make things happen. My aim is for The Product Academy to provide you with a framework of support that will help you succeed.